-

Standard: ISO9001Number: 42322Q30241R1SIssue Date: 2022-06-06Expiry Date: 2025-06-05

-

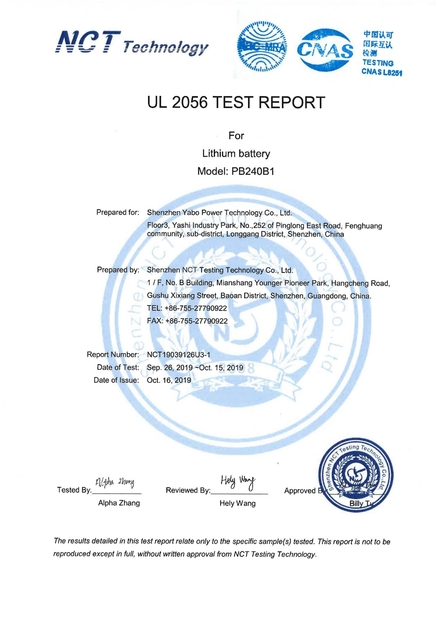

Standard: UL2056Number: NCT19039123U3-1Issue Date: 2019-10-06Expiry Date: 2026-12-27

-

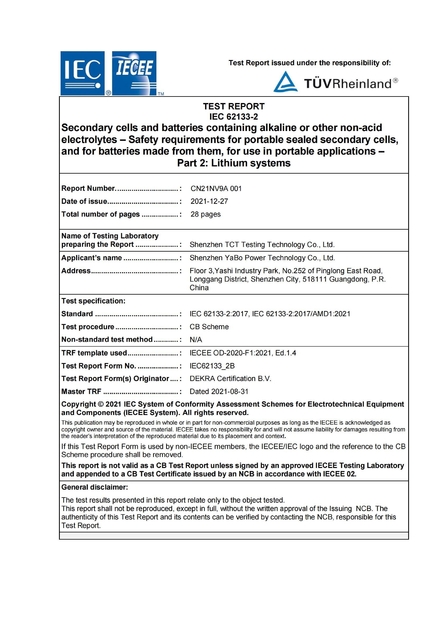

Standard: CBNumber: CN21NV9A 001Issue Date: 2021-12-27Expiry Date: 2026-12-27

-

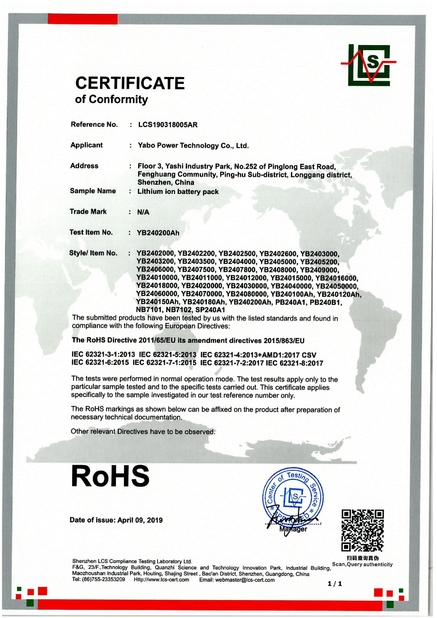

Standard: ROHSNumber: LCR190318005ARIssue Date: 2019-04-09Expiry Date: 2026-04-10

-

Standard: CENumber: 18230EC00028701Issue Date: 2020-04-10Expiry Date: 2026-04-10

-

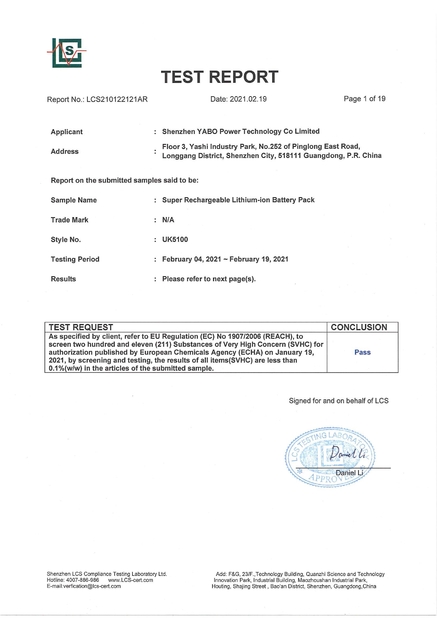

Standard: REACHNumber: LCS210122121ARIssue Date: 2021-02-19Expiry Date: 2026-09-20

-

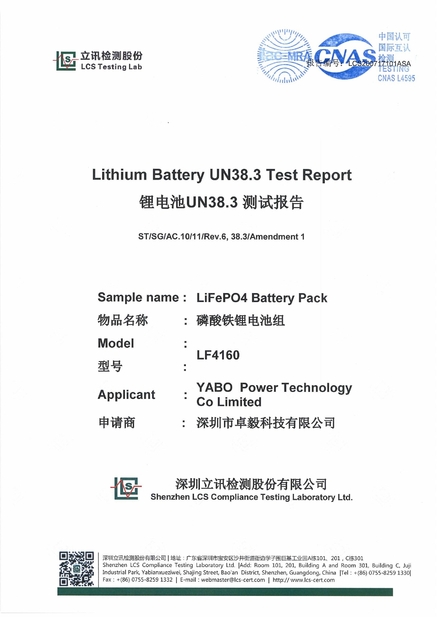

Standard: UN38.3Number: LCS200717101ASAIssue Date: 2022-01-01Expiry Date: 2024-01-01

-

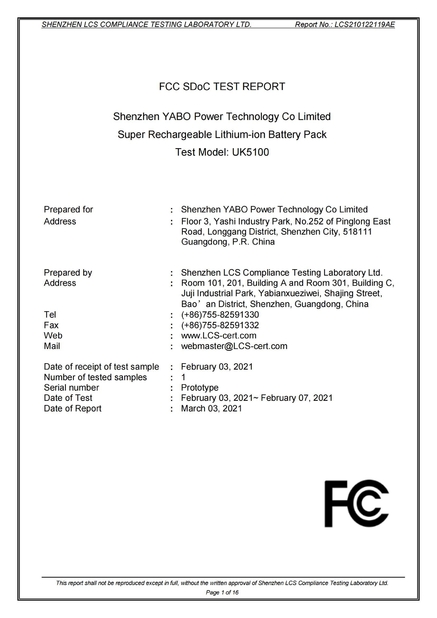

Standard: FCCNumber: LCS21022119AEIssue Date: 2021-03-03Expiry Date: 2026-03-03

-

Standard: MSDSNumber: ECT20220808001DIssue Date: 2022-08-11Expiry Date: 2026-08-11

YaBo has stickly quality control system, and we already got the ISO 9001 certificate since year of 2013.

From the raw materials to the end products, our QC and engineers keep monitoring the process step by step, make sure the quality of the end products 100% match customer's requirements.

![]()

for lifepo4 cells, we can use our automatic sorting machine, choose the cells which has close voltage, capacity and internal resistance to

battery packs, this ensure the cycle life of the battery packs.

![]()

Automatic welding machine, Integrated energy negative feedback laser control technology to achieve the consistency of welding effect from beginning to end;

![]()

when the battery pack is done, connect the battery pack with BMS . The intelegent BMS is choosed according to applications' working parameters(example: working current, peak working current, working voltage range, charging requirement)

Our Intelligent BMS system has many kinds of protection, such as overcharge, overdischarge, charge overcurrent, discharge overcurrent, short circuit and so on. It can track and display battery operation status, battery history and operation errors. Support 485, CAN

![]()

When the end product is done, we will do aging and run 2-10 cycles to make sure the performance is 100% match customer's requirement.

Our battery testing machine and the aging machine.

![]()

![]()

When this final part is done, the battery will pack well and delivery to your address.

To conclusion: Incoming materials inspected 100% to make sure materials used are qualified, also the QA team will make audit to all the suppliers we cooperate. QC staff will check all procedures and each working position during product-ion, and for each production line, there are QC staff to check the functions and performance of the product, after production finished, all products will be tested 100% and aged 100% for at least 6 hours, after packing, QC will also pick randomly from the products to check all functions, appearance and more.

YaBo power, power your life by providing you quality and affordable batteries.